The Character "Lampwick"

The Character "Lampwick"

from Walt Disney's Pinocchio

|

This story, of course is about oil lamp wicks, and should not to be confused with the character from the 1940 Walt Disney cartoon Pinocchio!

The dictionary defines the word wick as:

wick: n. A bundle of fibers,

or a loosely twisted or braided

cord, tape, or tube, usually

made of soft spun cotton threads,

which by capillary attraction

draws up a steady supply of the

oil in lamps, the melted tallow

or wax in candles, or other

material used for illumination,

in small successive portions,

to be burned.

There are many factors that are involved in the efficient burning of a lamp apart from fuel type and purity and burner design. The wick has many properties that affect the way the burner performs. It needs to be naturally absorbent or it needs to have a strong capillary action between non absorbent fibers. The liquid oil is drawn up into the wick by capillary action and vaporized by the heat of the flame; the burning takes place just above the wick. A thin layer of the liquid is present at the wick's surface. Because the liquid layer prevents oxygen from getting to the wick material, the wick doesn't burn up. The heat of the flame does convert the top of the wick to carbon, often called "char."

Warranted 32 Yards of "B" Wick - for #2 burners.

Warranted 32 Yards of "B" Wick - for #2 burners. |

Most wicks that you will find are made of cotton or other natural fibers. There were a number of attempts to make wick of other materials, such as wool, felt and fiberglass, but they don't appear to have garnered a large enough share of the market to make them economically successful, and few examples exist today.

James Donohue of Philadelphia, Pennsylvania, received a design patent (

D24,437) for a decorative lamp wick on June 25, 1895. His claim states: "The leading feature of the design consists in the arrangement of parallel stripes of contrasting shades on the obverse surface and oblique lines of contrasting shades on the reverse surface." I wonder if they were ever manufactured?

Make-Do Lamp Wicks --

A correspondent gives the Columbia Guardian the following useful bit of information:

"It might interest some of your readers to know this when it is so difficult to get lamp-wicks that the tops of old home-knit socks cut into strips of the proper width, make as good ones as the best that ever came from Yankeedom."

A correspondent gives the Columbia Guardian the following useful bit of information:

"It might interest some of your readers to know this when it is so difficult to get lamp-wicks that the tops of old home-knit socks cut into strips of the proper width, make as good ones as the best that ever came from Yankeedom."

--from the Atlanta Southern Confederacy, November 7, 1862

|

|

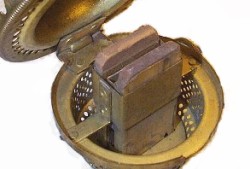

Different burners take differing styles of wicks: some burners take a round, string or rope wick; many take a flat wick; center draft lamps take tubular wicks. Some argand or side draft lamp burners take flat wicks and make them round by forcing it through a circular wick tube. Some of these actually use two wicks, each of which forms a semi-circle, and completes the circle as it emerges through the wick tube. Some examples can be seen in the left-hand margin.

Charles F.A. Hinrich & Chas. Reistle's patent burner

Charles F.A. Hinrich & Chas. Reistle's patent burner

Patent number 203,342, dated May 7, 1878

|

Charles F.A. Hinrichs of New York, New York, is probably best know in the lighting community for student lamps, an inventor and marketer of C.A. Kleemann's St. Germain or German Student Lamp. It should be noted that Hinrichs was quite involved in developing a viable alternative to the cloth fiber wick ("combustible carbonaceous material" he calls it) - a non-combustible wick comprised of various compounds containing mineral wool, asbestos, refractory cement, slacked lime, ground brick, plaster of paris, and other "ingredients." At least three patents of Albert Angell, all assigned to Hinrichs, predate any of Hinrich's own patents. Hinrich's also collaborated with Charles Reistle on this project. Both Angell and Reistle had a number of patents relating to student lamps as well. Should the reader desire more information on these burners and wicks, the individual patents are listed in the

patent table below and make for some interesting reading.

IMPROVEMENT IN LAMP WICKS --

|

| Figs. 1 & 2 |

"Our engravings show a novel substitute for the cotton lamp wick. The wick, two forms of which are shown in Figs. 1 and 2, are made of glass, and are filled preferably with pulverized gypsum, although any finely-ground stone, mineral, or metal may be employed. The bottom of the glass tube is closed by wire gauze, or other suitable strainer, through which the fluid flows; and is carried by the capillary attraction of the pounded material to the top of the wick.

Thus a permanent wick is obtained, which may be employed with any form of lamp, and will last for an indefinite time. It may also be used in connection with an open cup, which the inventor terms a poor man's lamp. A perforated card is laid upon the top of the cup or tumbler as a support to the wick.

It may be used either with or without a chimney, and it is claimed that with good kerosene oil it is perfectly safe, and consumes less of it, while it may be also used as a candle.

Patented through the Scientific American Patent Agency, September 14, 1869, by Edward D. Boyd, of Helena, Ark."

--SCIENTIFIC AMERICAN, JANUARY 1, 1870

|

|

Proper wick maintenance is essential to a properly functioning and efficient burner. Besides keeping the burner clean, the wick needs to be trimmed to even the exposed surface and remove excess charring. A number of innovations were conceived over the years to aid in wick management.

Trade Card - Duckworth & Company

Trade Card - Duckworth & Company

From Mount Carmel, Connecticut |

A number of wick trimmers were invented which ranged from modified scissors to elaborate cutting mechanisms. Improvements in burner manufacture that aided in wick maintenance were plentiful. One such "wick cleaner" invented by C.E. Baldwin was a bent wire, manufactured as an integral part of the burner, that could be moved over the lighted wick to "prevent the formation of carbon incrustations." This device is often found on the large Edward Miller burners on chicken brooder lamps. Hinged deflectors and galleries, allowing easy access to the wick were one of the most common innovations. Other burner modifications included removable galleries and galleries that could be elevated on a rod or piece of flat brass stock, like the

Adlam's Burner. The

Hyde Wick Adjuster enabled fine adjustments to be made to the wick without trimming. George H. Hyde of Boston, Massachusetts received US patent number 211,160 for his invention on January 7, 1879.

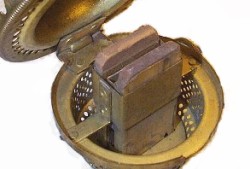

William Charles Seaton's Wick Trimmer

William Charles Seaton's Wick Trimmer

Pat. No. 254,390, February 28, 1882 |

Wick trimming devices were likely commonplace in early households. Scores of variations existed, especially in the form of modified scissors. Many early examples can be found in antique shops today and usually at a reasonable price - a worthwhile addition to any lamp collection. Other incarnations were not as readily identifiable. The device, left, patented by William Charles Seaton, of Quebec, Canada is an early patent model. This wick trimmer uses a rotary brush housed within to clean the wick. The wick is inserted through the slot and the rotating wheel will brush off the carbon particles. This looks like it would be quite awkward to use. This device was patented on February 28, 1882, and was assigned patent number 254,390. See the

patent table below for a list of wick/wick trimmer patents.

Care of Lamp Wicks --

- When filling for the first time or after putting in new wick, allow the wick to become thoroughly saturated before lighting.

- Don't cut the wick. Turn it up so only the charred portion is exposed and rub off evenly from left to right.

- Re-wick about once in two months if used every evening.

--from Directions for Care of B&H Lamps

- Trim the wicks right or this lamp will not burn right.

- Trim the wicks until there are no points on the flame and you will get a big round brilliant flame.

- Cut off the corners of the wick! This prevents smoking and makes the flame round.

- Remember - keep trimming the wicks until there are no points, and you will have a large, clear flame.

--from instructions for use of Angle Lamps

|

|

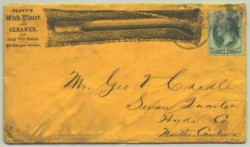

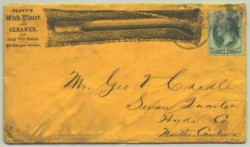

Illustrated Advertising Postal Cover for

Illustrated Advertising Postal Cover for

Platt's Wick Placer and Cleaner - [+] Image |

Here's an interesting piece of ephemera advertising Platt's Wick Placer and Cleaner for Dual Wick Lamps. I have not seen the genuine article, but they were obviously produced. I cannot find any patents on this item, but I will speculate that it was invented by Anson Platt of Philadelphia, Pennsylvania. Platt had at least four patents for lighting items, including three for multi-wick, argand-type burners. His patents are as follows: #33,402 dated October 1, 1861; #44,138 dated January 31, 1865; and #78,607 dated June 2, 1868. This device would be a logical accompaniment to his burner designs. Other patented devices to aid in the insertion of wicks include H.N. DeGraw's patent number 37,495 dated January 27, 1863; and W.Y.A. Boardman's invention dated December 4, 1866, patent number 60,130.

The wick chart

The wick chart shown below, as well as these images, will give the reader a sense of the comparative sizes of the common sizes of American wicks. Unfortunately, these sizes are not absolute and there are a number of variations between lamp makers. Many of the branded lamps took special wicks and were not of a standard size or thickness. To get a better sense of the variations, you may

view page 121 of the Simmons Hardware Company's Lamp Catalogue No. 468 from 1905-06. This is a fairly comprehensive list of wicks and gives their standard dimensions, both width and length. This is an invaluable resource if you are searching for a wick for a lamp that doesn't already have one for comparison or measurement.

Left to right: 1/8" and 3/16" string/rope wicks; 3/8", 1/2", 5/8", 7/8", 1-1/8" & 1-1/2" flat wicks.

Common Flat Wicks

for Lamps & Lanterns |

Center Draft Wicks

for Miller Lamps* |

Number

or Size |

Letter |

Width in Inches |

Number

or Size |

Size in inches

(measured flat) |

| 0 |

E |

3/8" or 1/2" |

0 |

1-1/4" |

| 1 |

A |

5/8" |

1 |

1-7/8" |

| 2 |

B |

7/8" or 1" |

2 |

2-1/2" |

| 3 |

D |

1-1/2" |

3 |

4-3/8" |

| * Many of the branded lamps took special wicks and were not of a standard size or thickness. |

Miller Center Draft Wicks: showing sizes 0, 1, 2 & 3, dimensions as seen in the table above.

| Patents relating to Wick Manufacture and Design |

| 4040 |

21890 |

23801 |

29324 |

36277 |

37237 |

43097 |

45384 |

| 46059 |

108339 |

113833 |

115045 |

115524 |

123917 |

135252 |

177796 |

| 202358 |

208310 |

354267 |

37495 |

60130 |

D24944 |

D24437 |

. |

| Patents relating to Wick Trimming Devices |

| 45692 |

31915 |

149964 |

169091 |

169785 |

173977 |

176271 |

176850 |

| 177546 |

177875 |

179504 |

193052 |

193053 |

223027 |

247888 |

249818 |

| 254390 |

278075 |

283521 |

314779 |

332900 |

382050 |

431008 |

436934 |

| 448789 |

452289 |

458439 |

465125 |

511902 |

593262 |

622510 |

676236 |

| 751339 |

916881 |

1018745 |

1040757 |

1570194 |

24804 |

36590 |

45574 |

| 57064 |

80577 |

86868 |

92908 |

97776 |

142265 |

. |

. |

Charles F.A. Hinrich's Patents, or assigned to him,

for mineral wick & burner |

| 176920 |

183036 |

188490 |

178774 |

196148 |

186734 |

198981 |

179049 |

| 188542 |

. |

. |

. |

. |

. |

. |

. |

| additional patents will be added as they are discovered |

| D = Design Patent, RE = Reissue of an earlier Patent |

To view any of the above patents, enter the number in the box below and select Query USPTO Database. This will take you to the specific patent images on the U.S. Patent & Trademark Office Database. Learn more about the USPTO here.

Wick and Wick Trimmer Patents

Wick and Wick Trimmer Patents