Kerosene Trade Card

Kerosene Trade Card |

On August 27, 1859, Colonel

Edwin L. Drake hit "pay dirt!" Drake had succeeded in drilling the first oil well in Titusville, Pennsylvania. The well was only 69-1/2 feet deep, shallow by today's standards. It produced between eight and ten barrels of crude oil per day, although some accounts claimed as much as twenty. Within a few short months, oil fields were springing up across the north-western Pennsylvania country-side and the Petroleum Industry was born.

Kerosene to fuel lamps would soon become readily available and affordable to the masses. This phenomenon would spin-off another market - containers to safely store and dispense this new commodity.

Safety Oil Can manufactured by

Safety Oil Can manufactured by

The Impervious Package Company

|

The vast majority of households and businesses relied on kerosene for lighting. Everyone needed a suitable container and there was no shortage of inventors and contraptions to fill the demand. Kerosene cans were manufactured in a variety of sizes to fit the needs of the consumers and retailers alike. Large drums with pumps or siphons were made for shopkeepers to dispense kerosene into portable containers made for household use. They were made of many materials including tin, galvanized steel, brass, wood, and glass. Innovations, improvements and gimmicks would be made over the decades from the 1840's well into the 20th Century. See the

patent table below for some additional patents.

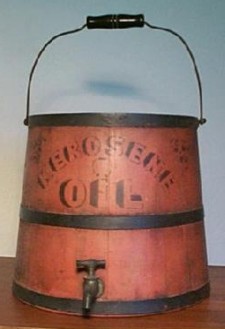

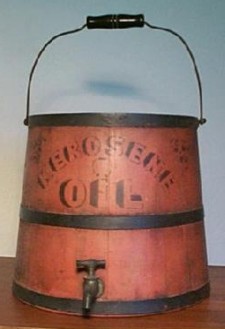

The Impervious Package Company of Keene, New Hampshire, manufactured "Impervious Packages" for holding oils, paints, varnish, turpentine & kindred substances. Their Safety Oil Can (picture at left) is an inverted wooden bucket - the shape of which is narrower at the top than at the base, with a spigot at the base to dispense the kerosene. The Safety Oil Can was available in a variety of sizes to suit every need: two, three, five, six, eight and ten gallon capacities. In 1886, the company boasted that "...we feel that we have every right to claim that our Oil Can is without a rival, and ranks as the safest, most reliable and convenient Family Oil Can in the world."

Daniel F. Bowker obtained U.S. patent number 181,241 on August 22, 1876 for improvement in barrels - manufacturing techniques to render the joints of the barrels perfectly tight and able to withstand the pressures of various liquids for extended periods of time. Bowker was from Keene, NH and the diagram is consistent with the Impervious can, but it is uncertain if the Impervious can was made under this patent.

Berger's Crystal Valve Glass One Gallon Oil Can

Berger's Crystal Valve Glass One Gallon Oil Can

|

The Winfield Manufacturing Company of Warren, Ohio, manufactured and distributed a number of kerosene cans. They made and sold Self Measuring Store Oil Tanks and Patent Family Oil Cans. Pictured here is Berger's Crystal Valve Glass One Gallon Oil Can, depicted in their 1906 catalog of Tubular Lanterns. They claimed that this product was well constructed, easy to use, and above all, safe. It was "made of heavy crystal glass and has a better protection of any other oil can." Berger's oil can is very similar to many cans that were produced during the period - a heavy glass oil container surrounded by a metal jacket or wire cage for added strength, with an attached wire bail for transporting. Most of these cans have cut-outs in the metal sleeve so that the level of the contents can be readily ascertained. Some of the named or branded containers are marked: DAISY, DANDY, DIAMOND, EMPRESS, GEM, HOME, QUEEN, THE FRIEND and VOGEL.

Dr. Milton H. Garland, residing at 332 Maple Lane, Englewood, Illinois, obtained patent number 284,408 on September 4, 1883 for a lamp filler. Garland utilized an interesting technique to market his filler cans. Garland "franchised" the rights to manufacture his cans to local merchants. He sold most of the component parts to the distributor, who would in turn have a local tinsmith furnish the remainder of the tin and assemble the can. The following parts were furnished:

Top plate of IX, charcoal tin, with date of patent.

Bottom of No 24, galvanized iron, stamped.

Fauset [sic] tube, bent by machine.

Tube for the fauset [sic] to fit perfect.

Blowing tube, three parts, all fitted.

Outside tube, to house the blowing tube.

Screw cap, leather lined.

Thimble to place the blowing tube on.

Cap for the thimble.

Bales with black handles.

Ears for the bales.

- from an 1893 advertising flyer

Garland sold the above items in sets of twelve; a set for two gallon cans cost 32 cents, a set for the five gallon cans selling for 38 cents.

Lewis O. Brown's pivoting oil can,

Lewis O. Brown's pivoting oil can,

pat. no. 532,867; January 22, 1895

|

The bodies, supplied by the distributors, were to be made of IXX charcoal tin or galvanized iron. He provided brief instructions for assembly.

He wrote that any good tinman should be able to produce 20 cans per day. Garland further reasoned that by purchasing the component parts, the buyer would save bulky freight and carting costs. Agents were permitted to sell parts to others to establish their own territory, but were requested to notify Garland so that he could keep accurate territorial records. If successful, Garland could have established a wide network of distributors selling his product and recruiting others to do the same. He was concerned about quality control and wrote: "Hoping that each party that buys the (patent) right will have none but good cans made, and by so doing be sure to succeed..."

Brown's pivoting oil can, seen above, was manufactured by the Brown Oil Can Company of Toledo, Ohio. This is Lewis O. Brown's patent number 532,867 granted on January 22, 1895. These have been observed with both metal and wooden framework supporting the galvanized tin pivoting can.

Hyman and Albert T. Hatch's oil can

Hyman and Albert T. Hatch's oil can

Patent #199,290 dated January 15, 1878

|

A.G. Belden & Company, located at 145 Maiden Lane, New York City, also manufactured a pivoting oil can - Belden's Patent Elevated Swinging Oil Can. Their model was more substantial and cumbersome - a rectangular can on a wooden frame. The container can be removed from the pivot and stored within the base for ease of transportation. It was made in one, two, three, five and ten gallon models, selling for $.65, .75, .85, 1.10 and 1.70, respectively.

The bright tin oil can, above right, is Hatch's patent can. Invented by Hyman Hatch and Albert T. Hatch, this can represents one of a manner of pneumatic oil cans. Hatch's patent was granted on January 15, 1878 and is U.S. patent number 199,290. Their design features a brass spout when extended outward, is in the open position. When swiveled around to allow the lid to close, it is in the closed position. The rubber bulb on the top applies air pressure to the vessel and forces the kerosene out when needed.

Night Lamp Filler

Night Lamp Filler

|

Small brass, copper or nickel-plated fillers are often found in today's market. These are considered to be fillers used for night lamps or other small-capacity lamp founds. Most have an air-tight seal on the fill cap and a thumb-operated plunger that would be depressed to break the vacuum and allow kerosene to be dispensed. Most night lamp founts only hold a couple ounces, so these would have been a clean, safe and convenient way to replenish the fuel, a chore often relegated to the children of the house.

| Patents for kerosene cans or processes used to manufacture them. |

| 181241 |

185483 |

228028 |

228159 |

272384 |

284408 |

336085 |

532867 |

| 3031 |

10036 |

33471 |

362474 |

363737 |

506153 |

511054 |

572502 |

| additional patents will be added as they are discovered |

| D = Design Patent, RE = Reissue of an earlier Patent |

To view any of the above patents, enter the number in the box below and select Query USPTO Database. This will take you to the specific patent images on the U.S. Patent & Trademark Office Database. Learn more about the USPTO here.

Some Kerosene Can Patents

Some Kerosene Can Patents