Pictured below are some lamp chimneys,

many are mold blown.

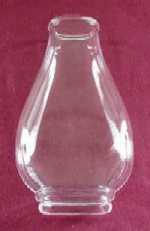

This is an example of a mold-blown chimney for a rectangular Leader burner. Most of these chimneys are produced in a two-piece mold and have mold marks, or seams, running down the sides. Most mold-blown chimneys have rough ground, not fire-polished tops & bottoms.

Showing an oval base chimney for a Pinafore burner. These were made in the same fashion as the above Leader chimneys. This particular example has embossing abound the base that reads: PAT. MAR. 30 '80

This is another example of a mold-blown chimney for a special burner base. Made by Dithridge & Co. of Pittsburgh, PA., it combines elements of both the oval and rectangular burners - flat sides and rounded ends. This chimney is also embossed on the base: P / UNDER PATS OF 1861, 1870

Here is a common style lip chimney with a plain top. This one still retains its original paper label that reads: M&C Co. Best Lead Glass Oil Finished

Here is a another mold-blown chimney made to fit a Drummond Burner. The chimney is oval in cross-section with a round base. It is held in the burner by two dimples that engage a tab and a spring lever on the burner.

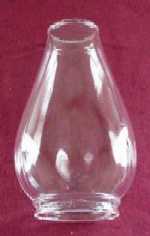

This is an example of a hand-blown chimney. These are commonly referred to as Sun chimneys, which was a trade name. They are also called "straight-side," "barrel," or "bullet" chimneys. These chimneys could be used on any prong burner, but were more commonly seen on the Collins Burner. They are frequently found on Hall Lamp Founts as they easily slid up into the top shade holder ring. |